Wood fencing offers classic charm but struggles with rot, pests, and heavy upkeep. Biobased composite fencing delivers superior durability, low maintenance, and eco-friendly performance, making it the smarter long-term choice for projects demanding style, safety, and sustainability.

Biobased Composite Fencing vs. Wood Fencing: Which One Truly Lasts Longer?

Why Longevity Matters in Fencing?

Choosing the right fencing material affects your project’s success for decades. While both biobased composites and wood fencing serve as effective barriers, their longevity differs dramatically in real-world conditions.

Architects and builders face increasing pressure to specify materials that perform reliably over time. The initial material choice impacts maintenance schedules, replacement costs, and client satisfaction throughout the fence’s service life.

This article examines the performance of wood and biobased composite fencing across durability, maintenance, environmental impact, and cost, helping professionals make informed, future-proof decisions.

Key Takeaways

✓ Biobased composite fencing outlasts wood by decades thanks to its engineered resistance to rot, pests, and weathering.

✓ Minimal upkeep gives composites a cost advantage over the long term.

✓ Sustainable construction goals are easier to achieve with biobased composite systems.

✓ Choosing biobased composite fencing ensures consistent performance, safety, and design quality across large and small projects.

Understanding the Materials

What Is Wood Fencing?

Wood fencing is a natural product, usually crafted from cedar, pine, or redwood. These species are chosen for their availability, workability, and natural resistance to some insects. Wood’s timeless appeal lies in its organic texture and warm colors.

However, as a natural material, wood is vulnerable to:

- Rot and decay from moisture exposure.

- Termite and carpenter ant damage.

- Cracking, warping, and splintering from sun and temperature changes.

Even when pressure-treated, wood still has limits. Its durability depends heavily on climate and ongoing care.

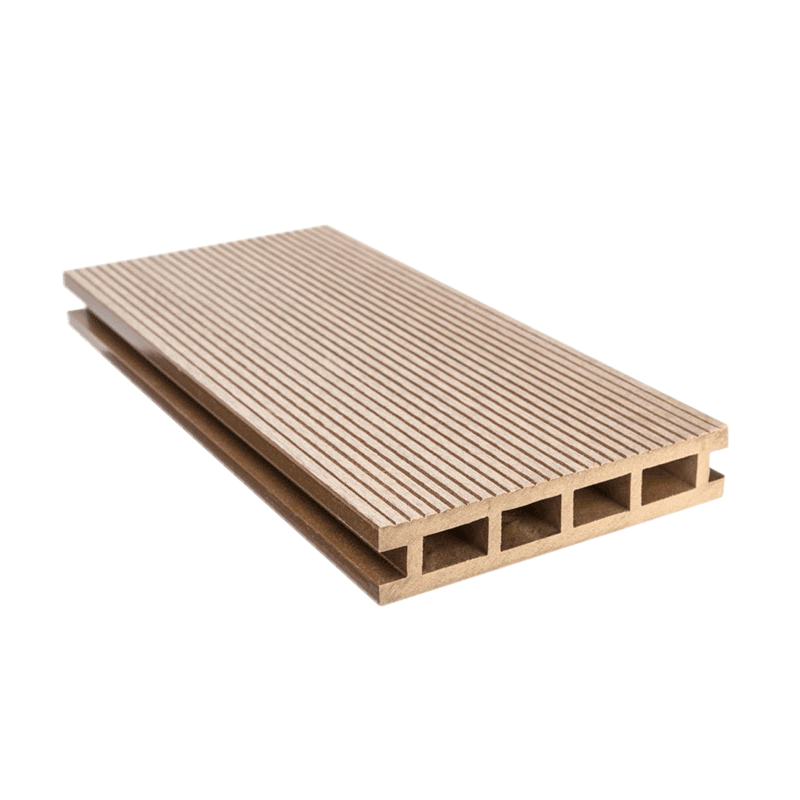

What Is Biobased Composite Fencing?

Biobased composite fencing combines natural fibers with biobased polymer resins. Many systems use recycled content, blending sustainability with engineering precision.

Biobased composite boards are designed for:

- Weather resistance without rotting or splintering.

- Consistency in texture and shape.

- A variety of colors and surface finishes that mimic wood grain or modern tones.

Unlike wood, composites are not dependent on chemical preservatives or constant refinishing to maintain performance.

Durability in Real-World Conditions

Lifespan of Wood Fencing

Wood fences can last 10-20 years depending on species, treatment, and climate. Cedar and redwood may push toward the higher range, while pine or untreated options often degrade faster.

Factors reducing lifespan include:

- Moisture: In humid or coastal areas, wood rots faster.

- UV exposure: Direct sunlight causes fading and drying, leading to cracks.

- Pests: Termites and borers can undermine structural strength.

According to the USDA Forest Products Laboratory, untreated wood in ground contact can fail in as little as 3-7 years, showing how conditions greatly affect service life.

Lifespan of Biobased Composite Fencing

Biobased composite fencing is engineered to resist the very challenges that weaken wood. It does not rot, warp, or splinter. With minimal upkeep, composite fences often last 25-30 years or more.

Benefits include:

- Stability in wet, dry, or coastal climates.

- Resistance to insects and fungus.

- Minimal expansion or contraction with temperature swings.

This predictable durability makes composites ideal for projects where consistency and performance over decades are required.

Maintenance: The Hidden Cost of Longevity

A fence is only as long-lasting as the effort put into maintaining it.

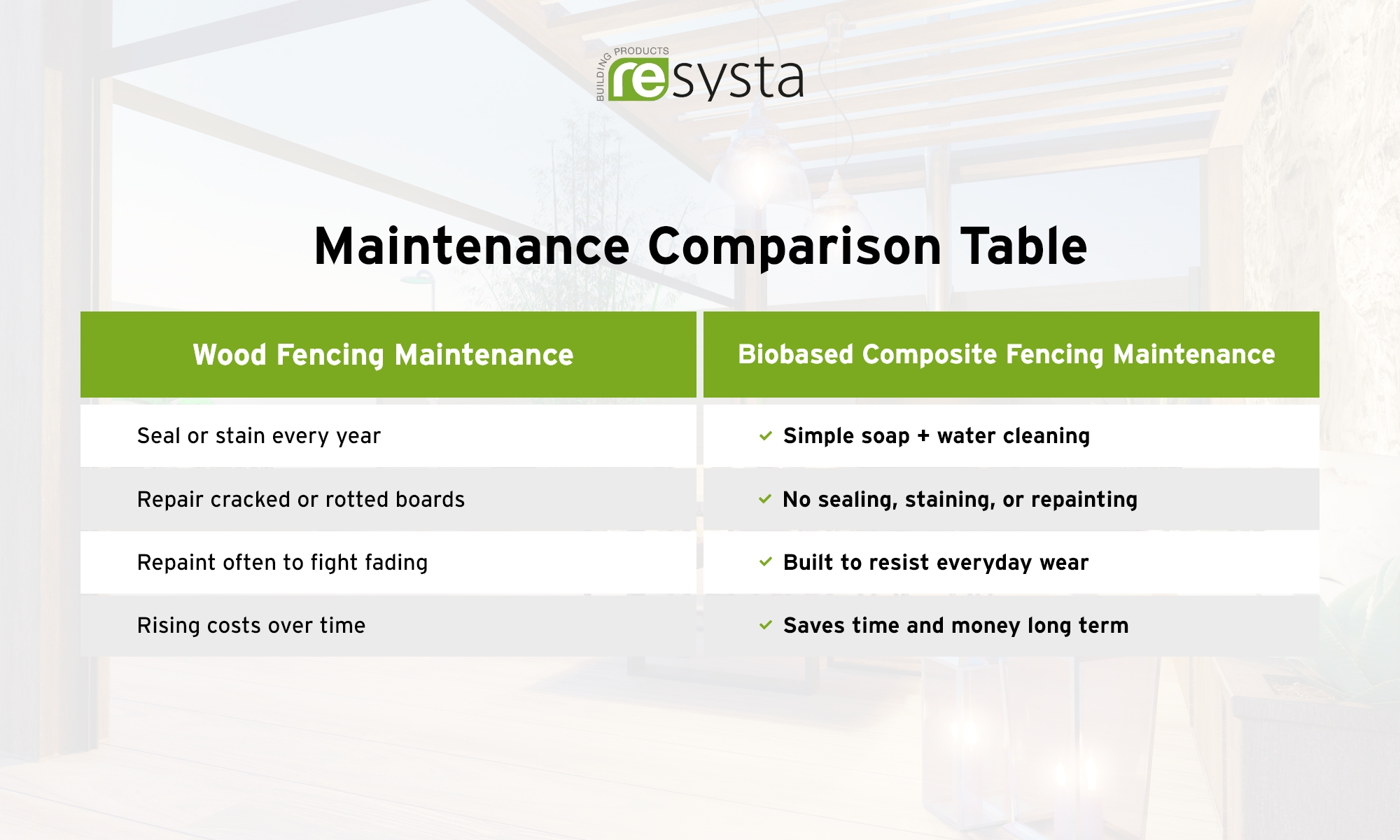

Wood Fencing Maintenance

- Annual sealing or staining.

- Repairs for cracked or rotted boards.

- Frequent repainting to combat fading.

- Costs accumulate over the years, adding to total ownership expenses.

Biobased Composite Fencing Maintenance

- Requires only occasional cleaning with soap and water.

- No staining, sealing, or repainting needed.

- Reduced risk of damage from common wear.

The difference in upkeep shifts the real value equation. Over 20 years, wood may demand thousands of dollars in labor and materials just to keep it functional. Composites largely avoid these hidden costs.

Sustainability and Environmental Considerations

Wood Fencing’s Environmental Impact

Wood is often considered renewable, but its environmental impact depends heavily on the sourcing and longevity of the material. When wood is harvested from unsustainable forestry practices, it contributes directly to deforestation, biodiversity loss, and increased carbon emissions. Even when responsibly sourced under forestry certifications, wood fencing still has a shorter service life compared to engineered alternatives.

Because wood fences require frequent replacement, staining, and repainting, they consume more raw material and chemical treatments over time. This cycle of harvest, manufacture, and disposal increases overall material consumption and environmental footprint.

According to the Food and Agriculture Organization of the United Nations, unsustainable timber harvesting remains a leading driver of global deforestation, highlighting the importance of choosing longer-lasting alternatives to reduce pressure on natural forests.

Biobased Composite Fencing’s Environmental Benefits

Biobased composite systems often include natural fibers and agricultural byproducts, reducing waste. Their long service life means fewer replacements, lowering the environmental burden over time.

- Lower maintenance reduces chemical use (stains, paints, preservatives).

- Long-term durability reduces landfill waste.

- Eligible for sustainable building certifications.

Resysta Building Products USA provides architects with a wood-alternative composite system that combines recycled rice husk and polymers, delivering a sustainable material choice while meeting LEED certification pathways by the U.S. Green Building Council.

Aesthetic and Design Longevity

Wood develops a patina as it weathers. Some may appreciate this look, but many see it as deterioration. Color fading and uneven weathering make wood harder to maintain aesthetically.

Bio-based composite fencing offers:

- Consistent colors and finishes that resist UV fading.

- Reliable uniformity across large-scale projects.

- Custom profiles and textures for modern or traditional styles.

This design stability makes composites attractive in residential neighborhoods, resorts, and commercial landscapes.

Structural Performance and Safety

Wood’s natural variability means knots, cracks, and density shifts. Over time, boards may weaken and splinter.

Biobased composite fencing, by contrast, is manufactured for stability and consistency. Benefits include:

- No splinters, safer for children and pets.

- Engineered strength against wind and impact.

- Reliable load resistance in perimeter and privacy fencing.

According to the National Association of Home Builders, engineered building materials reduce structural variability and deliver predictable performance across applications.

Cost Over Time: The ROI Perspective

Upfront, wood is often cheaper per linear foot. But the initial savings shrink when factoring in maintenance and shorter lifespan.

- Wood Fencing: Lower upfront cost, higher long-term maintenance, and replacement.

- Bio-based Composite Fencing: Higher upfront cost, lower long-term expense.

When measured across 25-30 years, composite fencing often proves the more economical choice, delivering higher return on investment through durability and reduced upkeep.

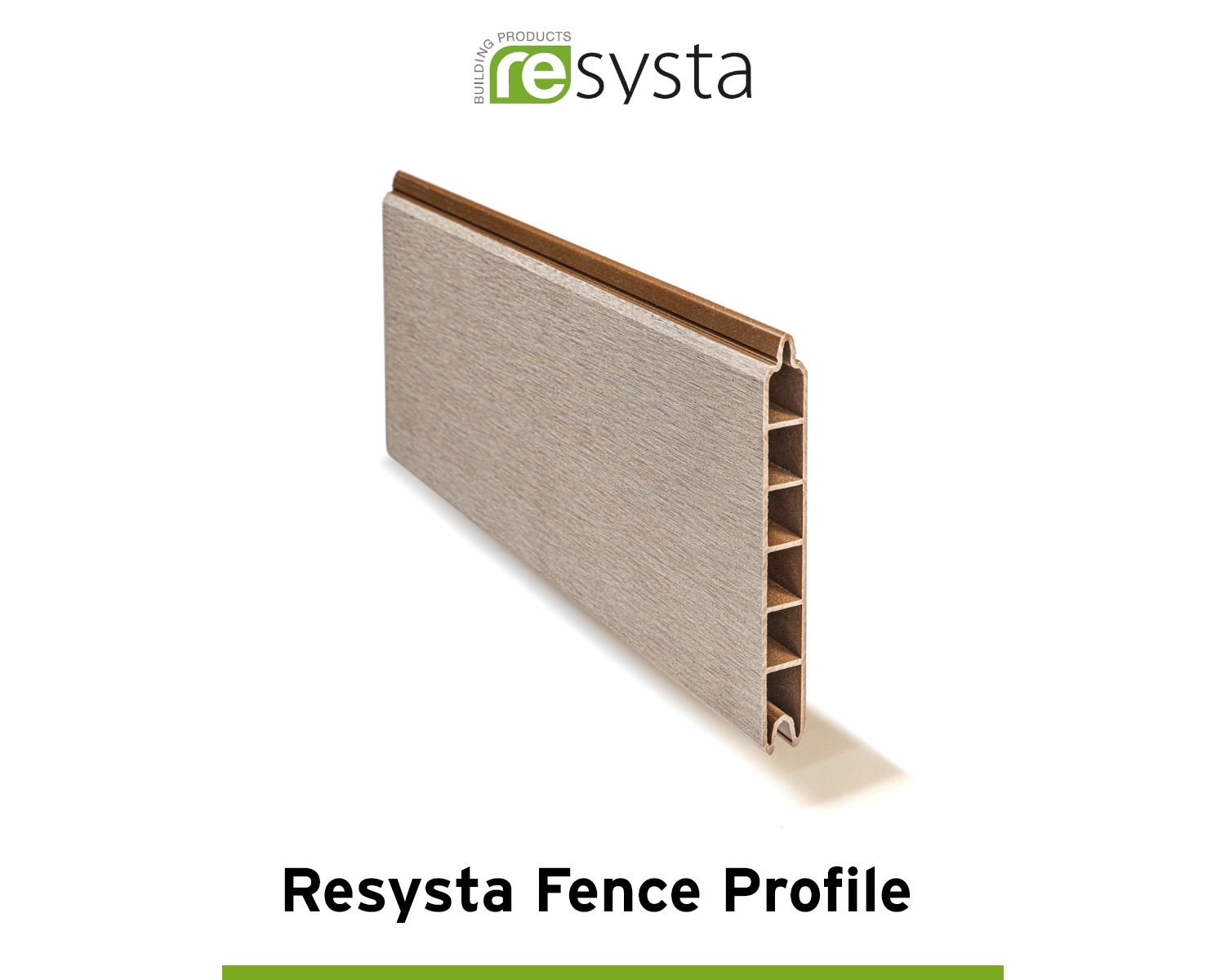

Spotlight on the Resysta Fence System

One standout option in the bio-based composite category is the Resysta Fence Profile. This system is designed to combine architectural appeal with long-term reliability.

Key features include:

- Eco-friendly composition: Made with rice husks, salt, and minerals, it avoids deforestation while reusing natural byproducts.

- Long-lasting performance: Engineered to resist rot, pests, cracking, and fading, even in demanding climates.

- Design flexibility: Available in modern finishes and customizable colors for residential, commercial, and resort applications.

- Complete system components: Includes inserts, posts, rails, and caps for seamless installation and structural stability.

The Resysta Fence Profile offers a refined balance of aesthetics, sustainability, and strength, delivering a fencing solution built to perform and impress for decades.

Final Verdict: Which One Lasts Longer?

After comparing the two materials, the answer is clear. Composite fencing consistently outlasts wood. Its engineered design resists decay, pests, and weather damage while minimizing maintenance.

For projects demanding durability, sustainability, and design consistency, bio-based composite fencing is the long-term performer.

Ready to build smarter? Explore sustainable and durable fencing options with Resysta Building Products USA. The advanced composite systems deliver strength, aesthetics, and peace of mind for decades. Order a FREE Sample now! https://resystausa.com/sample-order/

FAQs

How many years can biobased composite fencing last compared to wood?

Composite fencing can last 25-30 years or more, while wood often lasts 10-20 years, depending on climate and maintenance.

Does composite fencing need less maintenance than wood fencing?

Yes. Bio-based composite fencing only needs occasional cleaning, while wood requires regular sealing, staining, and repairs.

What climate conditions affect wood and composite fencing durability the most?

Wood struggles in humid, coastal, or termite-prone regions. Sustainable composite performs consistently in all climates.

Is composite fencing considered sustainable for green building projects?

Yes. Many composite systems use recycled materials and qualify for LEED credits, making them a sustainable option. Resysta composite fencing, made from rice husks, salt, and minerals, is designed to meet green building standards and contributes toward LEED certification pathways.