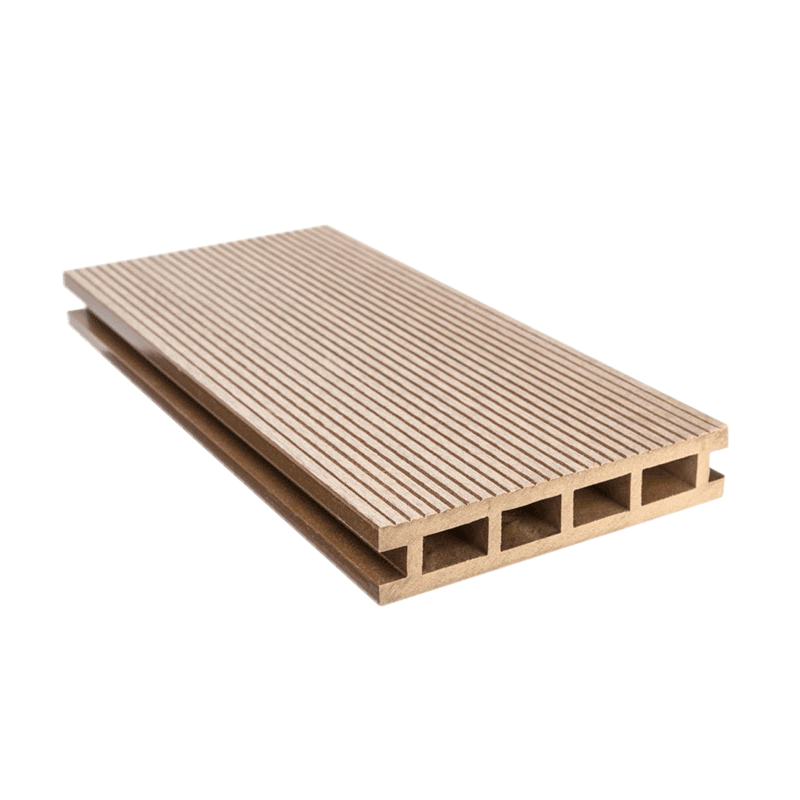

Homogenous extrusion

Material Resysta

RAW MATERIALS USED

| Rice husks Common salt Mineral oil |

approx. 60% approx. 22% approx. 18% |

MATERIAL CHARACTERISTICS

Density |

ASTM D2395:2002 |

approx. 1.46 g/cm³ |

Coeffivient of linear thermal expansion |

ASTM D696 |

3,6 x 10(-5) mC |

Water Absorption & Humidity |

ASTM D1037:2006a |

Little up to no water absorption (only surface moistening) |

Weathering and UV Resistance |

QUV Test |

With glaze treatment, Resysta surfaces are extremely resistant |

Fire Rating (german/european norm) |

EN ISO 11925-2 |

B2 (E) - standard flammable (with additional treatment B1 reachable) |

Fire rating according NFPA (US Norm) |

ASTM E84 |

Class A (flame propagation 25, smoke emission 450) |

Fire rating (British standard) |

BS 476 Teil 6&7 |

Class 1 |

Duraility Resistance against wood-destroying fungi (basidiomycetes) |

DIN V EN V 12038:2002 |

the material has not been affected, highest durability - Class 1 |

Emission |

LGA-tested safety & contamination |

LGA test passed |

Brinell hardness (HB) |

EN 1534 |

81,1 N/mm2 |

Coefficient of Friction |

Leather, Dry Condition |

0.687 |

Coefficient of Friction |

Rubber, Dry Condition |

1.082 |

Coefficient of Friction |

Neolite, Dry Condition |

0.850 |

Axial Witdrawal Force (of Screws) |

EN 320.2011-07 |

5777 N |

Thermal Conductivity (λ) |

EN 12664 |

0.199 W/(mK) |

Water Vapour Transmission |

DIN EN ISO 12572 |

5777 N |

Bending Strength |

ISO 178 |

46 N/mm² |

Bending Modulus |

ISO 178 |

3850 N/mm² |

Tensile Strength |

ISO 527 |

21,8 N/mm² |

Tensile Modulus |

ISO 527 |

2340 N/mm² |

Tensile Modulus |

ISO 527 |

2340 N/mm² |

Shearing Strength |

EN 392 |

16,8 N/mm² |

Durability - Resistance against rotting fungi |

CEN/TS 15083-2 |

No attack by the test fungi, highest durability class 1 (very durable) |

Durability against mold fungi and wood discoloring fungi |

EN 15534-1:2012 |

Durability against the wood discoloring fungi (very durable) |

Durability against subterranean Termites |

ASTM D3345-08 |

High Durability against subterranean Termites - nearly no weight loss |

Specific surface and volume resistances |

DIN IEC 60093 measuring voltage 100V |

Surface resistance Rx=8,0*10(13) Ω Specific surface resistance α=8,1*10(14) Ω Volume resistance Rx=2,2*10(13) Ω Specific volume resistance α=6,3*10(14) Ω |

Technic & Characteristics

Anyone working with wood will be enthused about Resysta. Like its natural relative it can be sawn, drilled, painted, sanded or oiled. However, there is one pivotal advantage: Resysta does neither crack nor splinter and its cutting wastes are 100% recyclable. The different profiles of Resysta are produced in an extrusion process can be used for many applications.

Attention:

General Safety Instructions and Instructions for Use

Do not burn the material! In case of fire, harmful chlorine gases and other degradation products may be released.

Not suitable for independent architectural structures.

Please make sure there is sufficient ventilation for the material during storage. Product should be covered and stored flat in a dry area

Do not treat it with strong (e.g. acidic or chlorinated) cleaning agents. Such may damage the surface of the material.

For the design with colors only use Resysta Stains to obtain the optimum color result.