Material properties

Resysta Material in comparison

|

cracking |

swelling |

splintering |

rotting |

insect infestation |

waterproof |

slip-resistant |

|

| Softwood |

|

|

|

|

|

|

|

| Hardwood |

|

|

|

|

|

|

|

| UPM Timber (Pine & Spruce) |

|

|

|

|

|

|

|

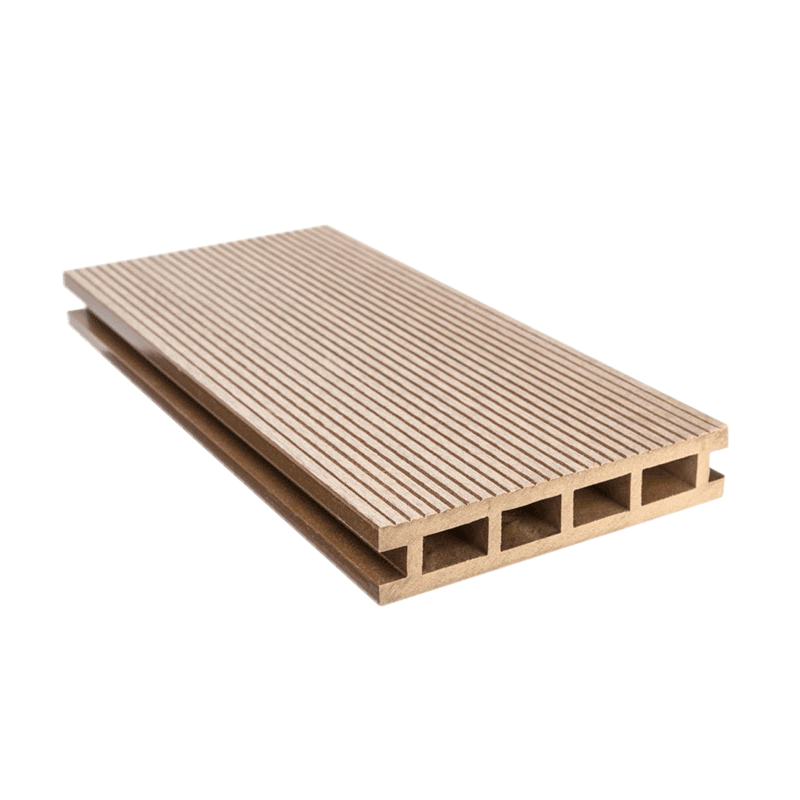

| WPC |

|

|

|

|

|

|

|

| Resysta |

|

|

|

|

|

|

|

Best result after 2000 hours, 15 materials tested

XENON TEST

Task:

In cooperation with the renowned „eph-Institut“ located in Dresden, Germany – Resysta carried out an „artificial weathering test of selected materials“. The Xenon test was chosen as test procedure.

Test Performance:

Artificial weathering was carried out for 2000 h (after 650 MJ/m2 irradiation) with a Xenon tester CI 3000 (test device KL 31) according to DIN EN 11341. Artificial weathering was conducted at the following test conditions:

- 55°C black standard temperature

- 50% relative humidity

- Radiation intensity 0.5 W (m2 x nm) at 340 nm

- Weathering cycle: spray cycle 18 min, drying phase 102 min

A factor of 15-25 can be applied to this 2000 h test. Assuming factor 20 and an average of 7 sunshine hours per day (Central Europe) this corresponds to a weathering period of 15 years.

The following assessments were carried out to characterize the weathering resistance:

- visual evaluation of color change by means of gray scale according to DIN EN 20105-A02

- visual evaluation after 500 h, 1000 h, 1500 h and 2000 h.

Test Material:

„eph-Institut“ was provided with 15 material samples with two test specimen each. One specimen of each version was subject to the weathering test.

IPE / TEAK

WPC

Resysta led in collaboration with the renowned Dresden “eph-Institut” a “artificial weathering of selected materials”.

The xenon test was selected as the test method.

Winner in the long-term test

CONCLUSION:

Resysta combines all the materials tested

natural look and feel are the most convincing with longevity.